GVI Application examples

Different application examples for GVI®

Aerospace

As part of the D2 mission, TEB accompanied the construction of a laboratory oven (up to 300° C with 10 mm insulation thickness); Sheet thickness of the shell structure: 0.1 mm; Various openings for sight glasses etc.

Battery enclosures

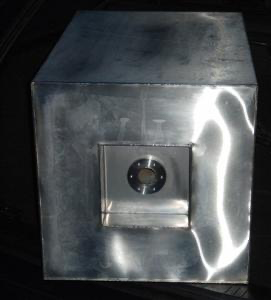

In the mid-1980s, highly effective, light, space-saving and yet mechanically highly resilient insulating housings for NaS batteries were required (350°C internal temperature; outer skin temperature approx. 10° to 15°C above ambient temperature with 22 mm insulation thickness).

After more than 30 years of intensive work on and with supported vacuum insulation, there are a large number of different application examples from a wide range of technical fields. Some examples are shown below.

Household and gastronomy

In this sector, it is primarily about (usually large) insulating containers for food and drinks

Laboratory

In the past, smaller special designs of cryostats and work vessels (for LN2) as well as measuring devices or special furnaces were manufactured for the laboratory area.

Apparatus engineering

In this environment, there are naturally numerous possible applications for high-quality insulation systems. In climatic chambers, (rapidly) changing temperatures are often simulated – thin insulation also has a low thermal capacity, so that the power losses when the temperature is changed are also low.

Heat protection containers are required to protect the electronics when data loggers are used to record the temperature in continuous furnaces.

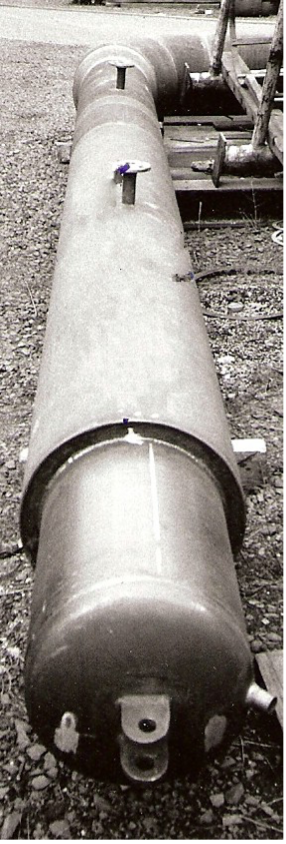

For the application in steel-jacketed pipes, the developments were carried out together with customers and successfully completed with the granting of an EU patent (EP0484491).

Energy/heat storage

With highly efficient vacuum insulation systems, sensitive heat can also be stored over long periods of time – this also makes seasonal storage for solar applications possible.

Buffer storage for district heating network

Automotive

Currently – with the switch to alternative drives – there are new, interesting areas of application for GVI® systems, especially in vehicle construction, e.g.

- Fuel cell / reformer at temperatures up to 600°/700°C

- Latent heat accumulator for engine preheating

There is also an increasing need for highly effective, thin insulation for heat recovery systems on combustion engines in order to significantly improve efficiency. The same applies to the storage of sensible heat – e.g. for heating the passenger cell.

Effective thermal management is required for all battery systems (e.g. Li-ion or NaNiCL). With the help of GVI® technology, multifunctional battery housings are created that enable both complete thermal management and crash-safe encapsulation of the battery, thus making an active contribution to environmental protection.

Transportation and Logistics

In addition to temperature-controlled food transport (but also e.g. certain chemicals or adhesives), there are high requirements for insulated containers, especially when transporting medical and pharmaceutical products! See also www.kryo-safe.de

Special variant “Controllable thermal insulation”

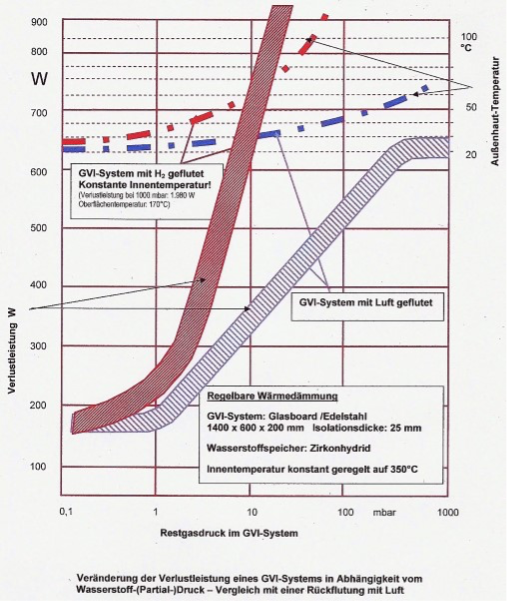

The introduction of minimal amounts of gas with particularly high heat conduction (e.g. helium) into the insulation gap almost completely breaks down the insulation effect, so that large energy flows can be dissipated via the surface if necessary (the partial pressure of the heat-conducting gas only has to be increased slightly for this purpose). If the design is appropriate (choice of gas storage material; GVI® system and filler), the necessary quantities of gas can be released from getter-like materials and then “pumped” back again so that the insulation is fully functional again. The process is therefore reversible and can be repeated as often as desired.

Such systems have been extensively tested on NaS batteries.

VIP application in building construction

(Source: ZAE)

Building construction

In the construction industry, there are already numerous VIP applications for building insulation (see adjacent image).

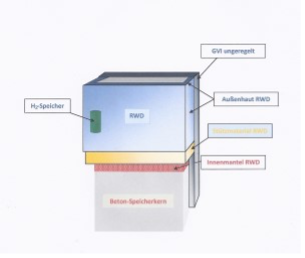

GVI® technology can also be used sensibly in building construction: with combined storage/heating elements, solar gains can be achieved and house walls can be used as storage.

Multifunctional wall construction as a combined storage and heating element